coating

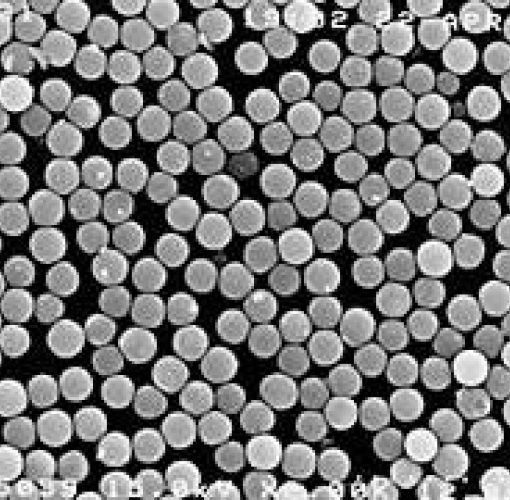

China is a large country of coating production and consumption, but at present, there are generally deficiencies in the performance of domestic coatings, such as poor suspension stability, thixotropy, weather resistance and washing resistance, resulting in the need to import a large number of high-quality coatings every year. Some coating manufacturers in Shanghai, Beijing, Hangzhou, Ningbo and other places dared to innovate and successfully realized the application of nano silica in coatings. Once this nano modified coating changed the shortcomings of previous products, its main performance indexes were greatly improved except that the contrast rate remained unchanged. For example, the washability of exterior wall coatings was increased from more than 1000 to more than 10000, The artificial accelerated climate aging and artificial radiation exposure aging time were increased from 250 hours (pulverization level 1 and discoloration Level 2) to 600 hours (no pulverization, no discoloration of paint film, color difference value 4.8). In addition, the bonding strength between the film and the wall was greatly improved, the hardness of the film was significantly increased, and the surface self-cleaning ability was also improved.

rubber

Rubber is a kind of elastomer with excellent elasticity, but its comprehensive properties are not satisfactory. During the production of rubber products, carbon black is usually added to the rubber to improve its strength, wear resistance and aging resistance. However, due to the addition of carbon black, the products are all black and the grade is not high. The advent of Nano-SiO2 in China has laid a material foundation for the production of a new generation of rubber products with novel color and excellent performance. After adding a small amount of nano Si02 in the ordinary rubber, the properties such as strength, wear resistance and aging resistance of the products reach or exceed the top grade rubber products, and they can keep the color unchanged for a long time. Nano modified color three ethylene propylene waterproofing membrane, its wear resistance, tensile strength, folding resistance, anti-aging properties are improved significantly, and bright colors, excellent color retention effect. Some progress has also been made in the development of color tires. For example, the flexural performance of tire side rubber has been improved from 100000 times to more than 500000 times. It is expected to realize the colorization of domestic automobile and motorcycle tires in the near future.

Pigment (dye)

Although organic pigments (dyes) have bright colors and strong coloring power, their general light resistance, heat resistance, solvent resistance and migration resistance are often inferior to inorganic pigments. By adding nano Si02 to surface modification of organic pigments, not only the aging resistance of pigments is greatly improved, but also the brightness, hue and saturation are improved to a certain extent, and the performance can be compared with imported high-grade products, which greatly widens the grade and application scope of organic dyes.